這個精彩絕倫的“大鉆石”建成后受到很多建筑師的關注,精彩的背后,其實有很多從未遇到過的挑戰。下面就來分享這背后的精彩故事吧。

The glass facade of "The Diamond" has caught the attention of many architects since its completion. There were many challenges behind this remarkable project. Now, let me tell you the story behind it.

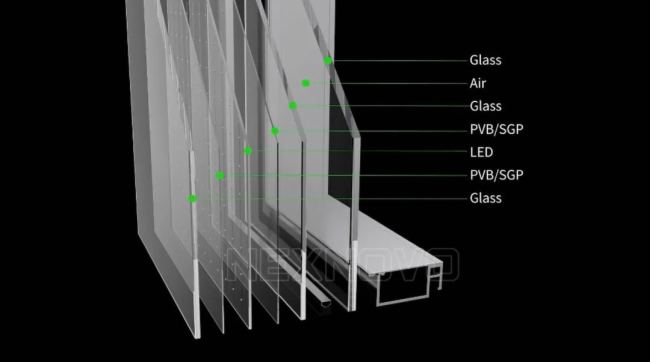

挑戰一:把嬌弱的LED燈珠和高強度的幕墻單元結合在一起。

眾所周知,建筑幕墻必須符合嚴格的安全規范,不同結構、高度、造型、尺寸都會影響幕墻單元的安全性。而LED燈珠比較脆弱,怕壓力、怕靜電、怕潮濕,兩層安全玻璃把LED燈珠夾里面,要經過高達1.5 MPa 的干法夾膠玻璃生產過程,以及長達12小時的高溫過程。玻璃上的電子材料要考慮極端條件下的考驗,例如雨水、雷電等影響,LED及其整個電子系統必須在極高的安全措施下才能正常工作。

Challenge One: Integrating delicate LED lamps with high-strength Insulated Glass Units.

The curtain wall design must meet strict safety standards. Factors like building height, structure, and design affect safety. Since LED lamps are sensitive to pressure, static electricity, and moisture, they are sandwiched between tempered glass layers. During the dry lamination process, which lasts 12 hours at high temperature and up to 1.5 MPa pressure, the LEDs must withstand these conditions. NEXNOVO also ensured the electronics work safely under extreme weather, such as heavy rain and lightning. Overall, the LED systems had to meet very strict safety requirements.

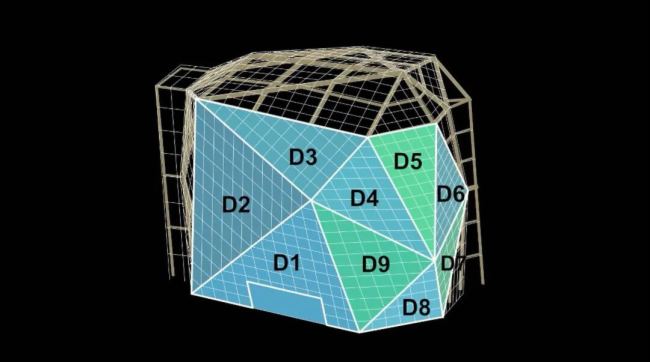

挑戰二:高度定制,精準交付。

這個項目一共有9個切面,有410塊形狀各異的幕墻單元。從設計、材料采購、生產、測試到安裝的整個過程涉及上下游企業數十名工程師、數百名工人以及數千萬個具體操作。所有人員必須協調工作,任何一個設計、生產的失誤,都將導致幕墻單元無法安裝或無法顯示畫面,甚至出現漏水、短路等情況。

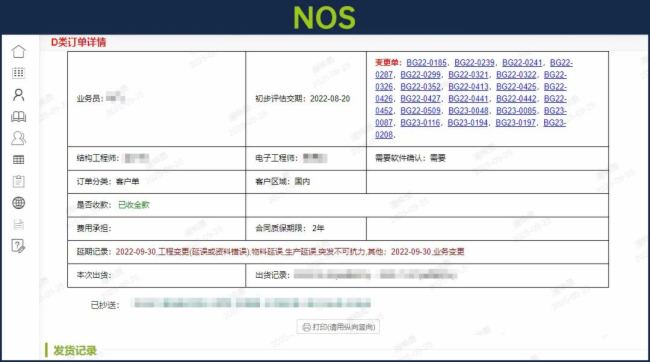

晶泓科技使用自研NOS管理系統,對項目進行全流程管理,每次設計更改,材料更新,以及現場情況的變化,都會在NOS上得到準確的記錄。即使在項目完成數年后,仍能準確追溯到任何一個材料及維修記錄。NOS系統全流程準確管理,為客戶提供隱形保障和附加值。

Challenge Two: Precise customization and flawless execution.

"The Diamond" has nine unique sections with 410 specially shaped curtain wall units. The entire process, from design and material sourcing to production, testing, and installation; requires smooth coordination among dozens of engineers and hundreds of workers from different teams. Tens of millions of precise operations are involved. Any mistake could cause installation issues, leaks, or short circuits.

Thanks to NEXNOVO’s NOS (NEXNOVO Operation System), we manage the project from start to finish. Every change in design, materials, or site conditions is carefully recorded in NOS. Many modifications during the project are tracked, and even years after completion, all records can be precisely traced. This system provides clients with an added layer of safety and confidence.

挑戰三:畫面管理。

因為“大鉆石”有9個尺寸各異的畫面,而每一塊畫面也是由多塊異形的單元構成,在畫面控制上,需要把每塊單元統一連接起來實現有效的控制,最終呈現沒有“裂縫”的畫面效果。由于晶泓科技自研的SMART LED,每一顆LED燈珠都有一顆獨立的驅動芯片,通過系統的MAPPING技術,對LED燈珠實現逐點精準控制,最終實現畫面統一拼接。在播放端,先對畫面進行準確的“切割”再“拼接”,對用戶來說,把整個復雜的系統降低到“上手就會”的極致簡單的操作。

Challenge Three: Managing the display system.

"The Diamond" has nine sections with different shapes and sizes, each made up of many irregular units. To create a seamless visual, all units need to connect smoothly.

NEXNOVO’s patented SMART LED lamps, with built-in driving ICs, enable flexible control of each LED. This allows precise mapping of the LED matrix to coordinate all five sections. At the playback stage, the system cuts the image into pieces and then stitches them together, making operation simple for the user.

飛利浦LED屏

飛利浦LED屏 聯建光電LED屏

聯建光電LED屏 威創小間距

威創小間距 洲明小間距

洲明小間距 AET小間距

AET小間距 奧拓LED屏

奧拓LED屏 aoc

aoc 青松光電LED屏

青松光電LED屏 WAP手機版

WAP手機版 建議反饋

建議反饋 官方微博

官方微博 微信掃一掃

微信掃一掃 PjTime

PjTime